Exclusive Dealer for WESTERIA products in Taiwan, Philippines, Malaysia, Vietnam

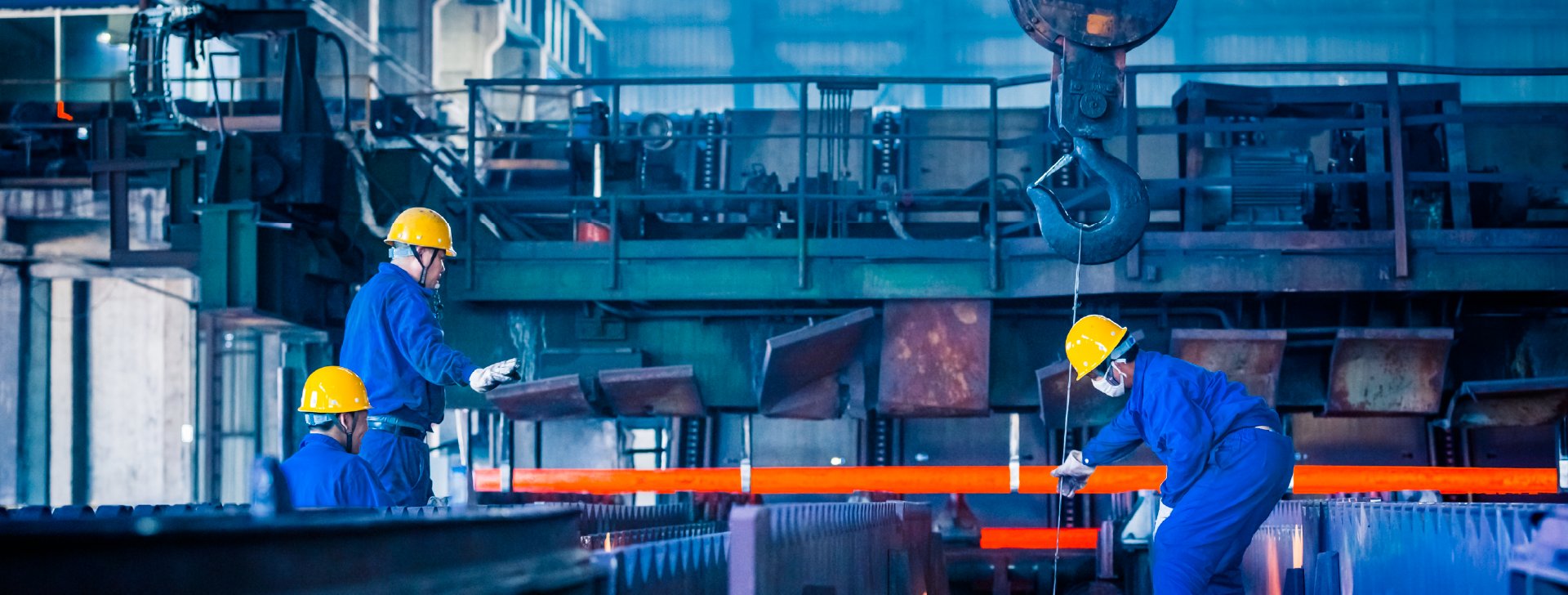

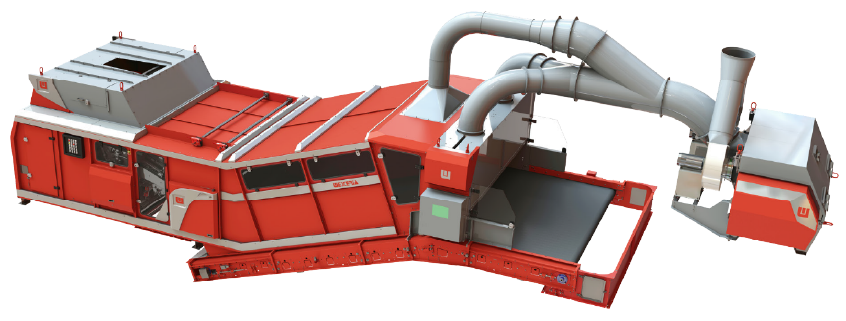

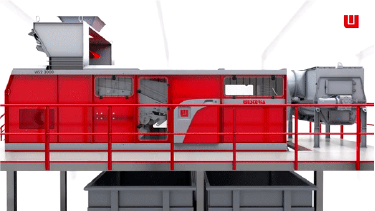

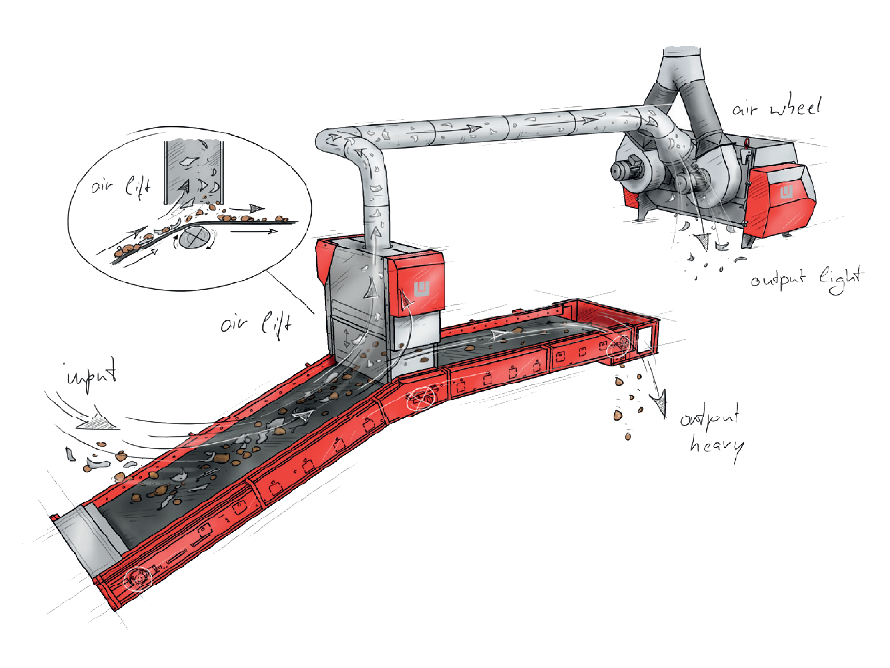

Pneumatic separation of various types of waste such as construction waste, compost , household waste , slag or scab material

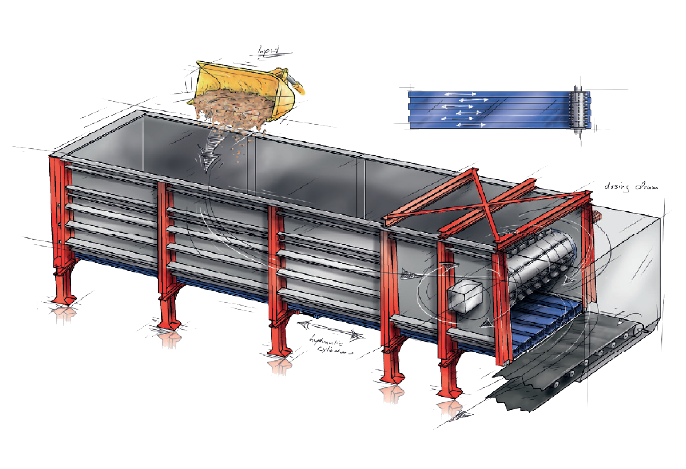

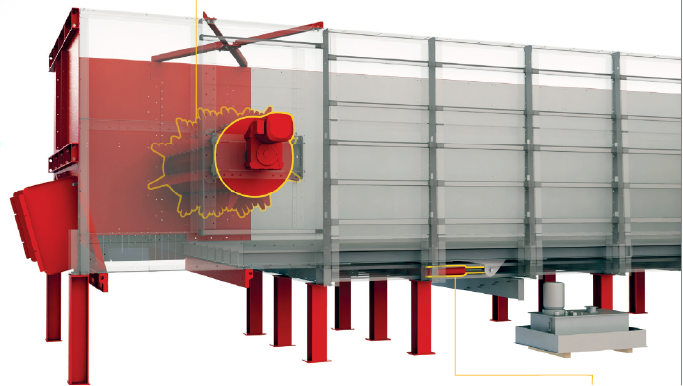

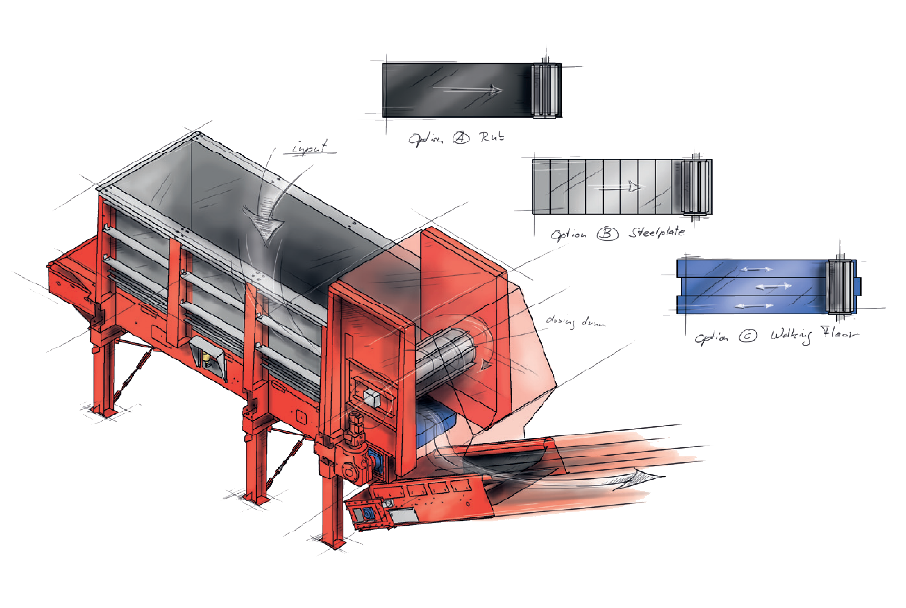

Feeding / Buffering / Bunker

Pneumatic separation of materials with similar specific density

Feeding / Buffering / Bunker used for materials such as foils/PET-bottles, dry goods, such as paper/carton or sharp-edged or hot materials

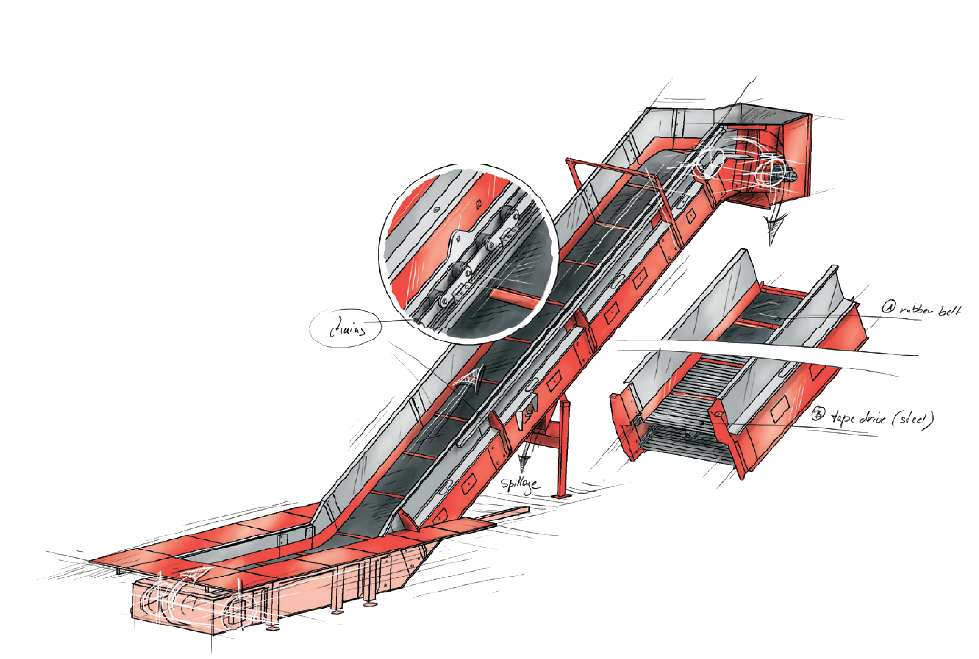

Conveyor belt systems for slopes up to 60 degree

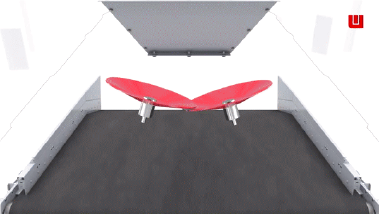

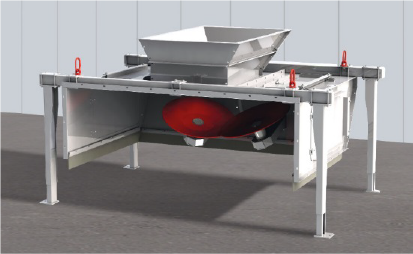

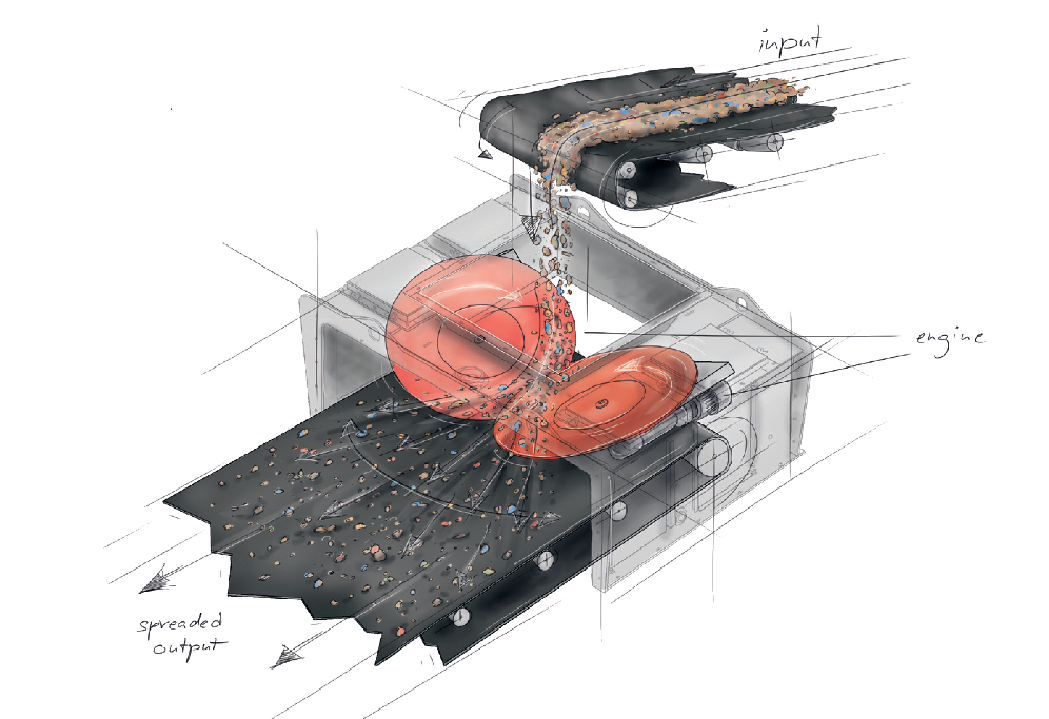

Material spreading system from 1500mm to 3000mm