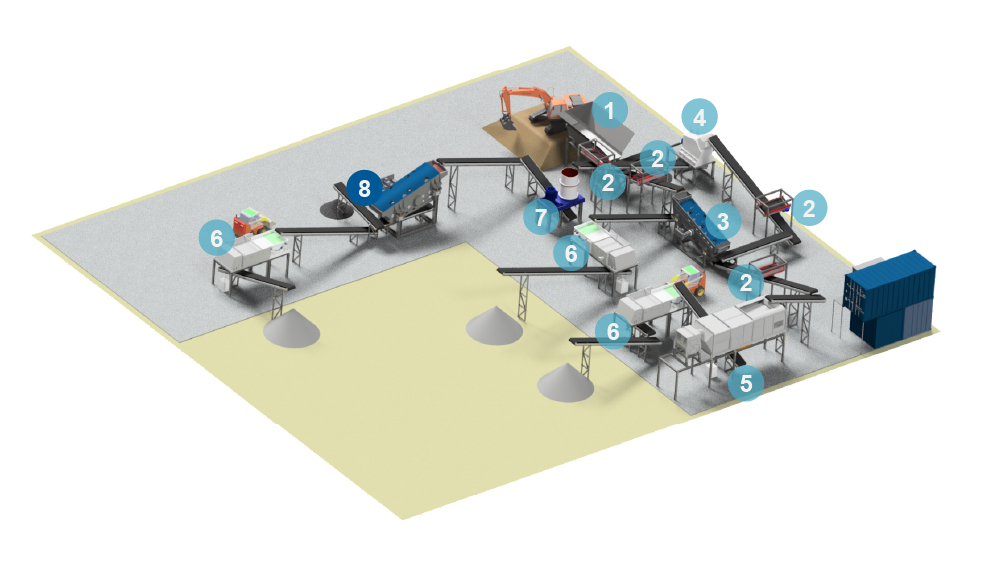

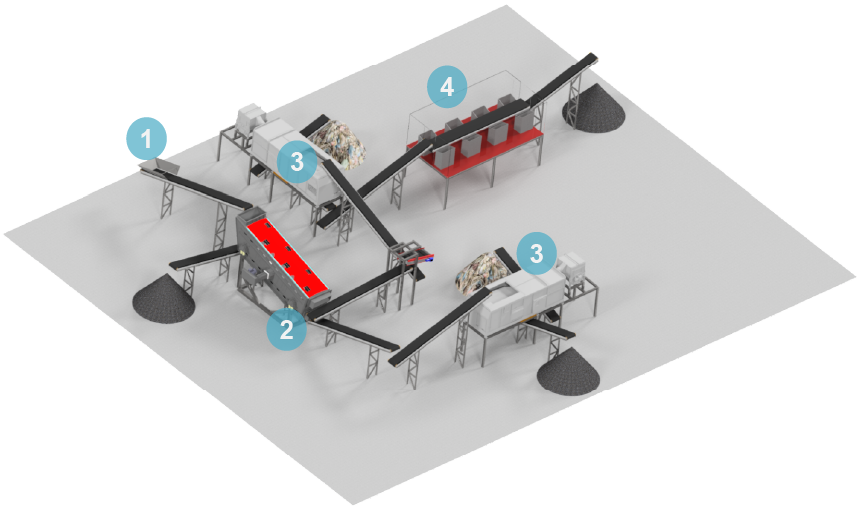

A incinerator bottom ash (IBA) application contains a separation of ferrous and non-ferrous metals, as well a separation via flip flow screen in different corn grain sizes from the input ash.

1

Incineration bottom ash feed and portioning

2

Reducing of bulky ferrous magnetic material

3

Separation of over size material

4

Homogenization of over sized material

5

Material sizing determinate in grain size by SPALECK double deck Flip-flow screen

6

Quality control

7

Extraction smaller ferrous particles

8

Separation of unburned residuals by WESTERIA Wind shifter

9

Separation of finest particles

10

Extraction of Non-ferrous metals

11

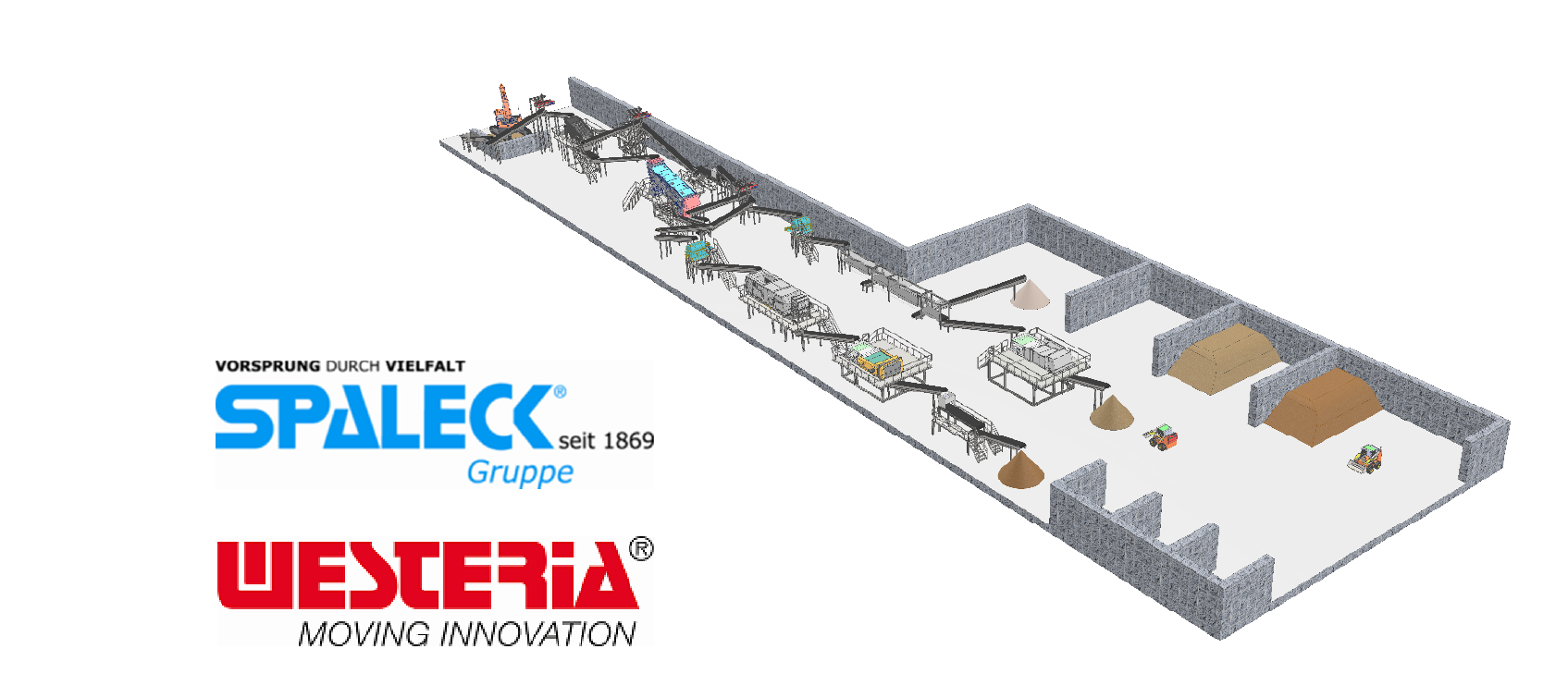

A incinerator bottom ash (IBA) application contains a separation of ferrous and non-ferrous metals, as well a separation via flip flow screen in different corn grain sizes from the input ash.

1

Incineration bottom ash feed and portioning

2

Reducing of bulky ferrous magnetic material

3

Separation of over size material

4

Homogenization of over sized material

5

Material sizing determinate in grain size by SPALECK double deck Flip-flow screen

6

Quality control

7

Extraction smaller ferrous particles

8

Separation of unburned residuals by WESTERIA Wind shifter

The soil municipal waste mix, mostly wet excavated, pre screened via drum screen with a 100 mm cutting size to separate bulky material in front. In a second fractionating step a 3D double deck screen separate oversized material over 50 mm from a middle fraction, 50 mm to 10mm and a fine fraction of under 10mm. The oversized and the middle-sized fraction are sent over via over belt magnet step and wind shifting step to a sorting stand.

1

Incineration bottom ash feed and portioning

2

Material sizing determinate in grain size by SPALECK double deck Flip-flow screen

3

Separation of unburned residuals by WESTERIA Wind shifter

4

Quality control

Soil washing a wet physical separation technique to separate different kind of grain sizes of soil sediments and ashes.

Most likely, the soil contamination is bounded to the fine material, or can be dissolved in the process – water, fine material will be separated and concentrated during the washing process and separated from the coarse and sand fraction. Heavy metal contamination can be separated as well as oil and chemical soil pollution bound to soil fractions.

1

Separation of gravel (mixing of contaminated soil in water)

2

Screening/ dewatering of organic and gravel particles

3

Separating of fine particles, by pressured circular movement of fluid

4

Sand corn and particle surface cleaning, scrubbing

5

particle dewatering via high frequency screening